TOROIDAL TRANSFORMER

The TOROIDAL POWER TRANSFORMER, core is wound by an orientated steel strip. There is no gap and the copper wire winding can be evenly distributed on the core, so that, the transformer has small magnetic leakage, low loss, small interference and high efficiency. And for use in environment with limited volume, such us height limit and outer diameter limit, toroidal transformer is easy to control. For the same power, can design according to customer's volume with small OD and high height or design with big OD and low height. The toroidal transformer custom design just has one center hole, is very easy to assembly.

Toroidal Transformer For Sale

-

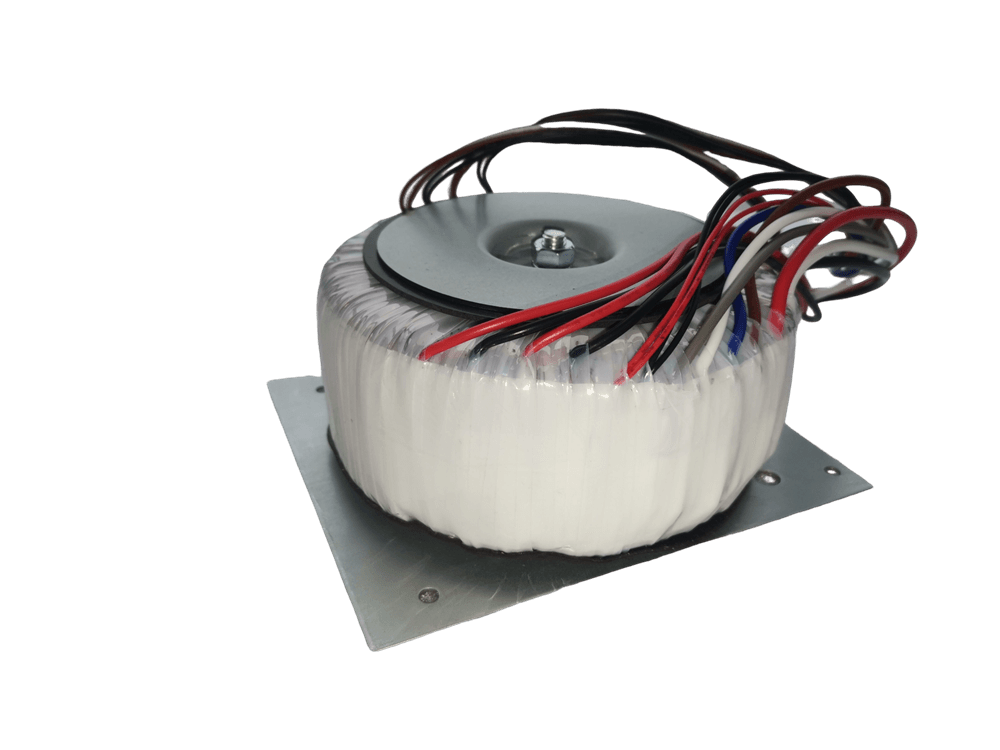

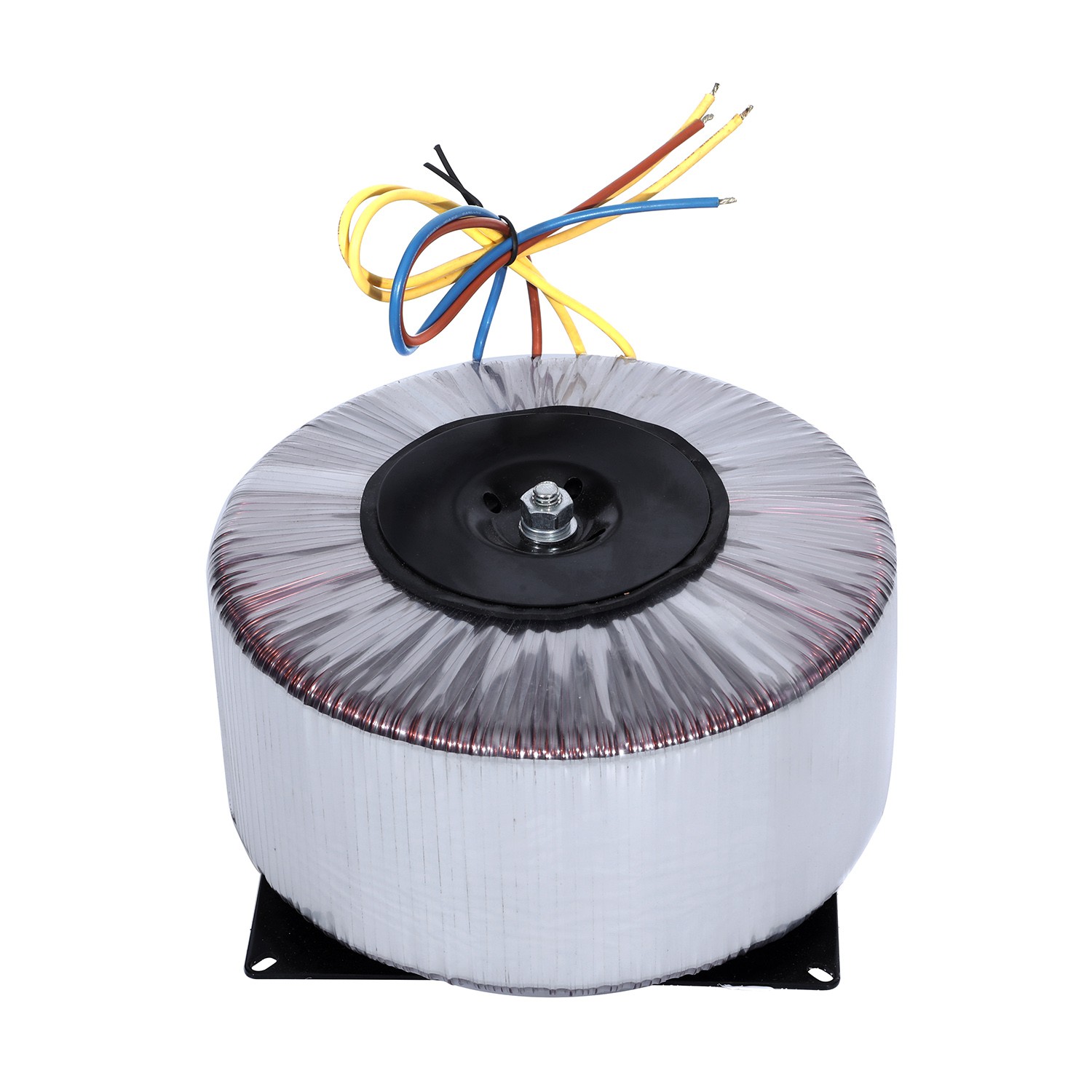

Transformer for AC Source Power Supply

POWER: 1200W

Read More

SIZE: 180 (OD) x 50 (ID) x 75(H) mm

Primary Voltage: 230V 47~63Hz

Secondary Voltage: customized

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

-

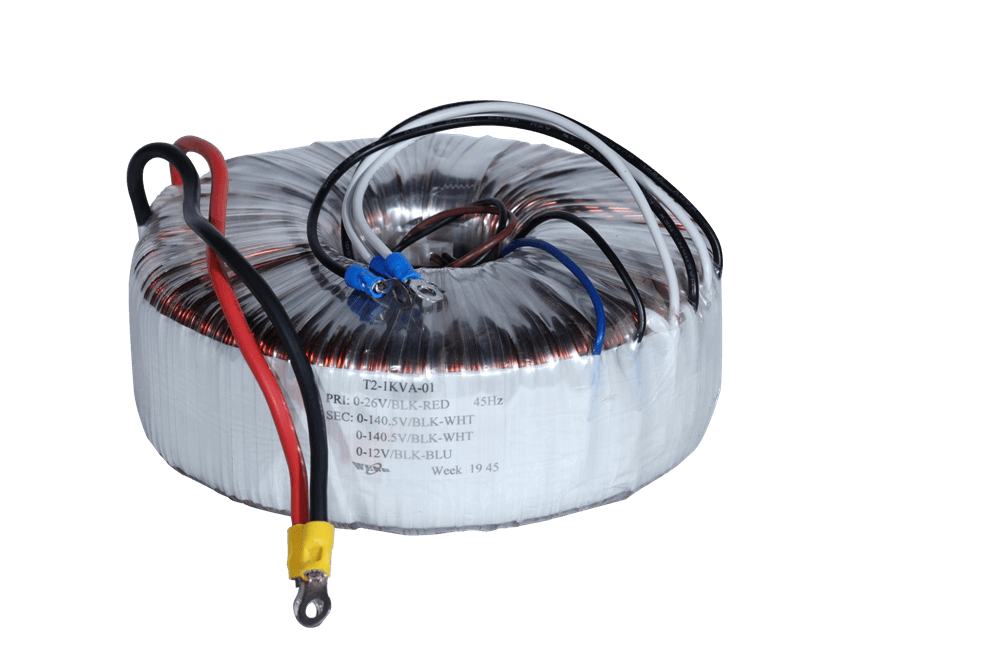

Transformer for Instrument and Apparatus

POWER: 700W

Read More

SIZE: 142 (OD) x 48 (ID) x 72(H) mm

Primary and Secondary voltage: customized

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

-

Transformer for Security System

POWER: 100W

Read More

SIZE: 80 (OD) x 37 (ID) x 55(H) mm

Primary voltage: customized

Secondary: 0-70V-100V

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

-

Output Transformer for Public Address System

POWER: OT-240W

Read More

SIZE: 90 (OD) x 37 (ID) x 30(H) mm

OUTPUT: 0-70-100V

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

-

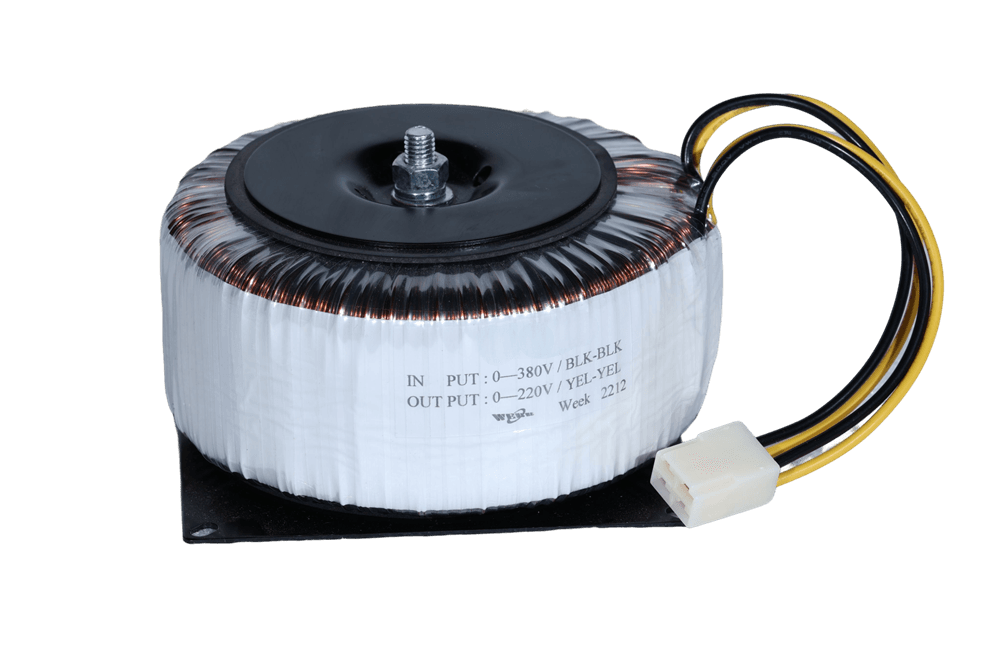

Auto Transformer for Industrial Control Equipment

POWER: 300W

Read More

SIZE: 100 (OD) x 45 (ID) x 50(H) mm

380V To 220V

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

-

Power Transformer for Public Address System

POWER: 120W

Read More

SIZE: 120 (OD) x 40 (ID) x 55(H) mm

Primary: Dual 115V

Secondary: 24V

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

-

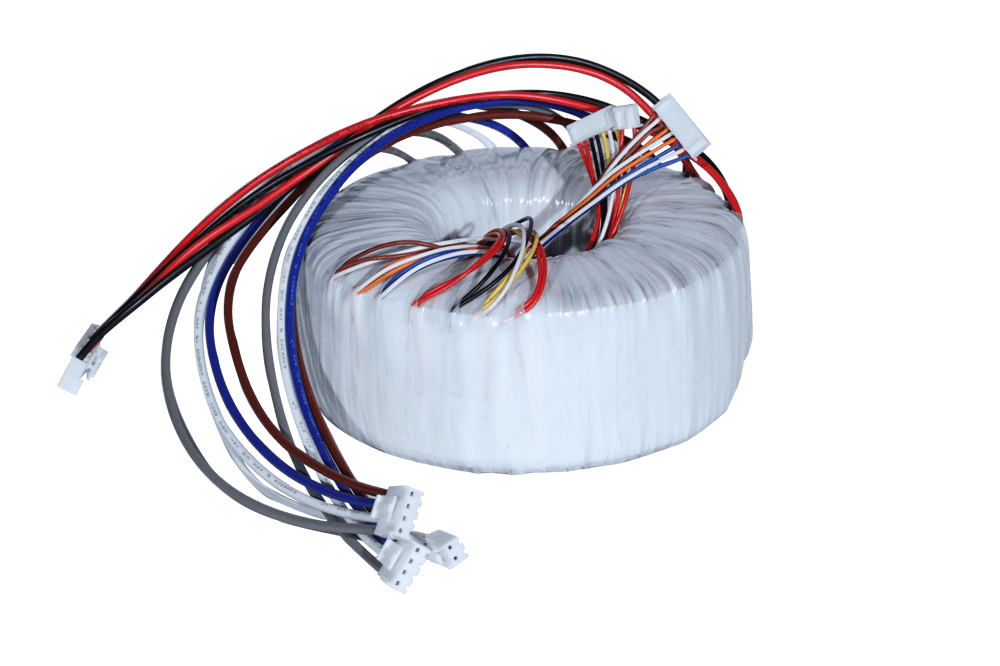

Power Transformer for Professional Audio Amplifier

POWER: 1500W

Read More

SIZE: 160 (OD) x 40 (ID) x 75(H) mm

Primary and Secondary voltage: customized

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

-

Transformer for Semiconductor Processing Equipment

POWER: 2300W

Read More

SIZE: 195 (OD) x 58 (ID) x 93(H) mm

Primary and Secondary voltage: customized

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

-

Transformer for Access Control System

POWER: 100W

Read More

SIZE: 100 (OD) x 45 (ID) x 38(H) mm

Primary: 240V

Secondary: 12V

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

Application field: Automatic Door System -

Transformer for Inverter Equipment

POWER: 1000W

Read More

SIZE: 162 (OD) x 52 (ID) x 72(H) mm

Primary and Secondary voltage: customized

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

-

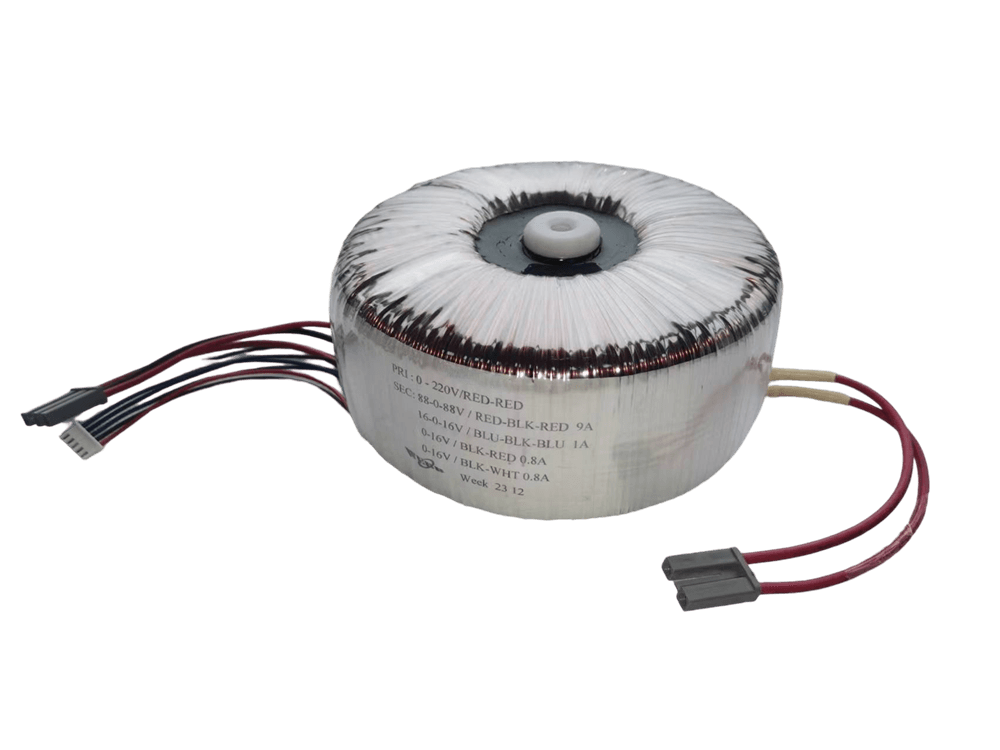

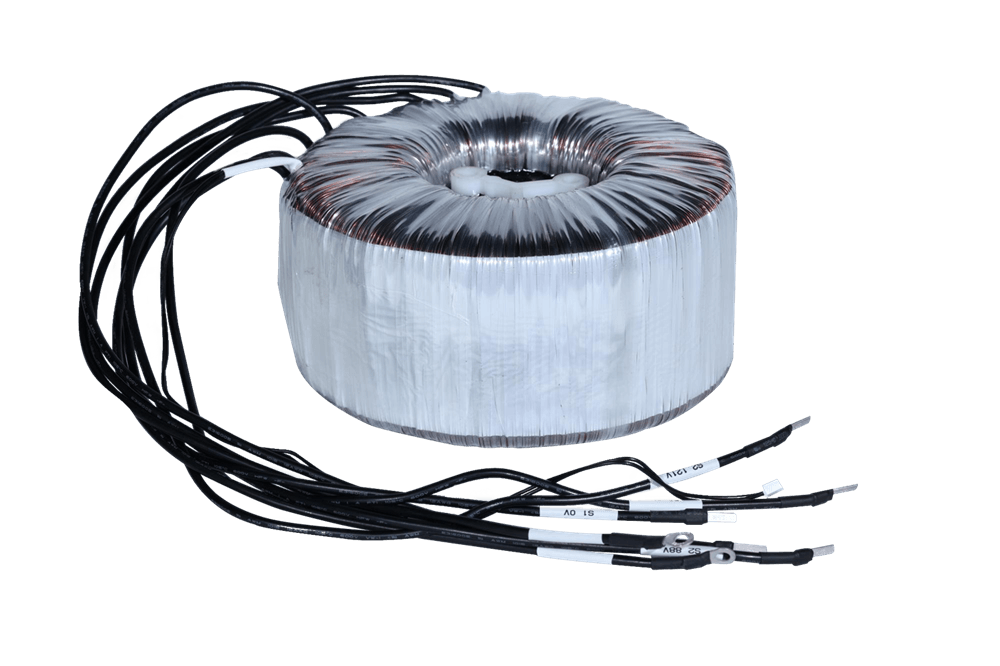

Transformer for Amplifier

POWER: 1300W

Read More

SIZE: 172 (OD) x 52 (ID) x 76(H) mm

Primary and Secondary voltage: customized

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

Application field: PA Amplifier,Guita Amplifier, Stage Amplifier, Tube Amplifier, Karaoke Amplifier -

Transformer for UPS (Uninterrupted Power Supply)

POWER: 2000W

Read More

SIZE: 181 (OD) x 53 (ID) x 100(H) mm

Primary and Secondary voltage: customized

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

Professional Toroidal Transformer Manufacturers

Advantages of Custom Toroidal Transformers

• Size Adaptability: Toroidal transformer designs can be manufactured according to the size requirements of a specific application.

• Weight and volume advantages: Custom toroidal transformers have obvious advantages in weight and size, which can achieve higher equipment integration and flexibility.

• Efficient energy transfer: Toroidal transformer designs can be optimized for specific needs to achieve higher energy efficiency.

• Electromagnetic interference suppression: It has low magnetic flux leakage and less electromagnetic radiation, and can be designed according to specific needs to improve the reliability of the overall system.

• Reliability and stability: It can be designed according to the load requirements and working environment of specific applications to provide higher stability and reliability.

How Does A Toroidal Transformer Work?

A toroidal power transformer increase or decrease the power supply according to the magnetic field passing through the secondary coil. The amount of voltage generated is related to the number of windings in the secondary coil compared to the main coil. The 2:1 ratio in the coil winding doubles the voltage. In other words, more loops in the secondary coil will increase the voltage.

FAQ

1.What does toroidal transformer do?

- Voltage Transformation:

- Isolation:

- Efficiency:

- Compact Design:

- Low Noise:

Overall, toroidal transformers offer several advantages including high efficiency, electrical isolation, compact size, and low noise, making them a popular choice for a wide range of electrical and electronic applications.

2.Why is a toroidal transformer better?

Toroidal transformers offer several advantages over traditional laminated-core transformers, making them a preferred choice for many applications. Here are some reasons why a toroidal transformer may be considered better:

- Efficiency:

Toroidal transformers are known for their high efficiency, typically ranging from 90% to 98%. The toroidal core design minimizes energy losses due to magnetic leakage and eddy currents, resulting in improved efficiency and reduced heat generation. This makes toroidal transformers more energy-efficient and environmentally friendly compared to other types of transformers.

- Compact Size:

The toroidal core design allows for a more compact and space-saving transformer compared to traditional laminated-core transformers. The toroidal shape provides a high magnetic coupling coefficient, allowing for efficient energy transfer within a smaller footprint. This makes toroidal transformers ideal for applications where space constraints are a concern, such as in consumer electronics, audio equipment, and medical devices.

- Low Noise:

Due to their symmetrical winding configuration and uniform magnetic flux distribution, toroidal transformers produce low levels of audible noise and vibration. This makes them well-suited for audio equipment, where noise and distortion can degrade sound quality. Toroidal transformers are also commonly used in sensitive electronic equipment and instrumentation where low noise and electromagnetic interference (EMI) are critical.

- Electromagnetic Interference (EMI):

Toroidal transformers exhibit lower levels of electromagnetic interference compared to laminated-core transformers. The toroidal core design helps to contain magnetic flux within the core, reducing stray magnetic fields and EMI emissions. This makes toroidal transformers suitable for applications where EMI must be minimized, such as in audio equipment, communication systems, and medical devices.

- High Isolation:

Toroidal transformers provide excellent electrical isolation between the primary and secondary windings, as well as between the input and output circuits. This isolation helps to protect sensitive electronic components and circuits from voltage spikes, noise, and other electrical disturbances. Toroidal transformers are commonly used in applications where safety and reliability are critical, such as in medical equipment, industrial machinery, and power supplies.

Overall, the combination of high efficiency, compact size, low noise, and low EMI makes toroidal transformers a preferred choice for a wide range of electrical and electronic applications. While they may be slightly more expensive than traditional laminated-core transformers, the performance benefits and reliability they offer often justify the investment.

3.What is the difference between toroidal transformer and normal transformer?

Toroidal transformers and traditional laminated-core transformers differ in several key aspects, including their construction, performance characteristics, and applications. Here's a comparison between the two:

Construction:

- Toroidal Transformer: A toroidal transformer features a ring-shaped magnetic core made of a continuous loop of ferromagnetic material, such as iron or ferrite. The primary and secondary windings are wound concentrically around the core, resulting in a compact and symmetrical design.

- Laminated-Core Transformer: A laminated-core transformer consists of stacked layers of thin ferromagnetic laminations, typically made of silicon steel. The windings are wound around the laminations, and the entire assembly is enclosed within a magnetic core.

Size and Weight:

- Toroidal Transformer: Toroidal transformers are generally more compact and lightweight compared to laminated-core transformers of similar power ratings. The toroidal shape provides a high magnetic coupling coefficient, allowing for efficient energy transfer within a smaller footprint.

- Laminated-Core Transformer: Laminated-core transformers tend to be larger and heavier due to the bulkier construction of the laminations and core assembly. While they may be suitable for higher power applications, they occupy more space and are less efficient in terms of size.

Efficiency:

- Toroidal Transformer: Toroidal transformers are known for their high efficiency, typically ranging from 90% to 98%. The toroidal core design minimizes energy losses due to magnetic leakage and eddy currents, resulting in improved efficiency and reduced heat generation.

- Laminated-Core Transformer: Laminated-core transformers have slightly lower efficiency compared to toroidal transformers due to greater energy losses associated with magnetic flux leakage and eddy currents in the laminations.

Electromagnetic Interference (EMI):

- Toroidal Transformer: Toroidal transformers exhibit lower levels of electromagnetic interference (EMI) compared to laminated-core transformers. The toroidal core design helps to contain magnetic flux within the core, reducing stray magnetic fields and EMI emissions.

- Laminated-Core Transformer: Laminated-core transformers may produce higher levels of EMI due to the presence of air gaps between the laminations, which can lead to increased magnetic flux leakage and radiation.

Noise:

- Toroidal Transformer: Toroidal transformers produce low levels of audible noise and vibration due to their symmetrical winding configuration and uniform magnetic flux distribution.

- Laminated-Core Transformer: Laminated-core transformers may generate more audible noise and vibration compared to toroidal transformers, especially at higher power levels, due to the presence of air gaps and uneven magnetic flux distribution.

Applications:

- Toroidal Transformer: Toroidal transformers are commonly used in audio equipment, medical devices, industrial machinery, power supplies, and other applications where compact size, high efficiency, low noise, and low EMI are desirable.

- Laminated-Core Transformer: Laminated-core transformers are used in a wide range of applications, including power distribution, voltage regulation, lighting, HVAC systems, and industrial automation, where higher power levels and cost-effectiveness are important considerations.

Overall, the choice between a toroidal transformer and a laminated-core transformer depends on the specific requirements of the application, including power rating, size constraints, efficiency, noise levels, and EMI considerations. While toroidal transformers offer advantages such as compact size, high efficiency, and low EMI, laminated-core transformers may be more suitable for higher power applications where cost-effectiveness and reliability are paramount.

Get Your Best Solution Today!

We take care of every procedure from design & development to prduction & testing.