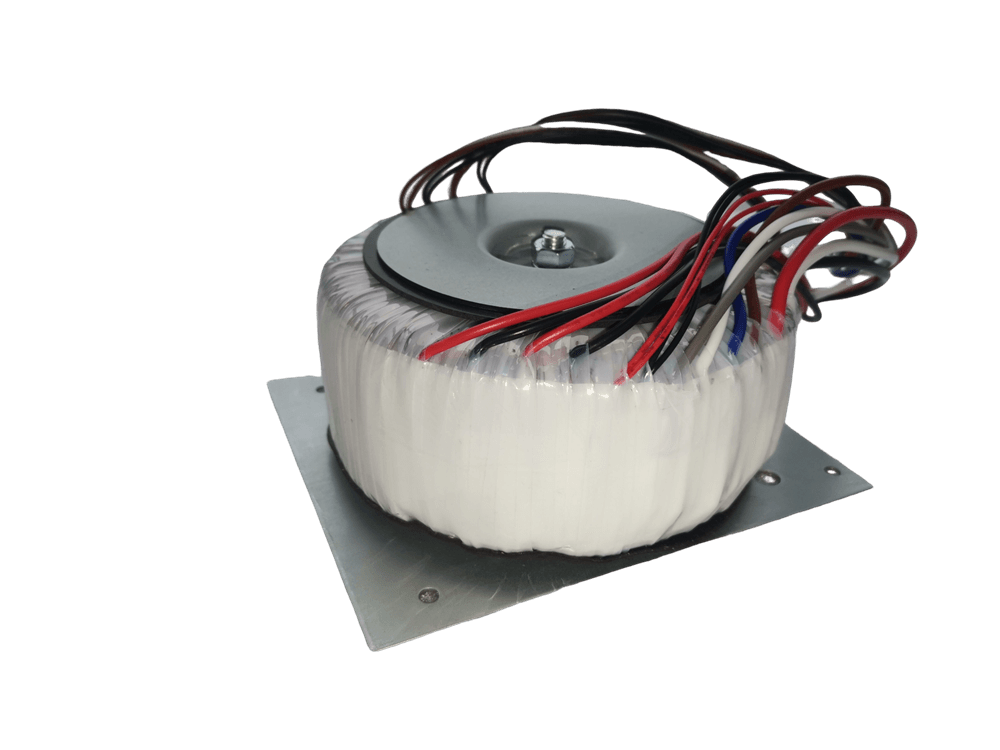

POWER: 1200W

SIZE: 180 (OD) x 50 (ID) x 75(H) mm

Primary Voltage: 230V 47~63Hz

Secondary Voltage: customized

Insulation systems: 105/130/155/180 degree are available.

Design to meet UL/CSA/TUV/VDE/CE and other safety requirements.

ROHS 2.0 Directive and (SVHC/REACH) are conformity.

AC source power supply transformer is the device installed in a power supply for voltage conversion. It has high request on the transformer. It requests the transformer must has high efficiency, power must be sufficient, small loss, Low interference resistance, small magnetic leakage, low temperature rise. For the AC source, it is better to choose toroidal structure. The magnetic circuit closure is good for Toroidal transformer. It can take full advantage of the magnetic properties of silicon steel, reduce the magnetic leakage of the core.

Product Feature:

1. The tranformer has wiring terminal at the end of lead wire, it is very easy to install.

2. Low magnetic leakage, low noise.

3. It is made with high permeability silicon steel and high quality copper wire(double insulated).

4. It can be made with temperature protector to ensure the safe operation of the transformer.

5. Can design accorinding to customer's working environment and working space.

NFC Transformer provides both standard and custom designs with following features.

Sample Lead Time: 3~5 days

Production Lead Time:3 Weeks (Urgent order can be negotiated)

Quantity:No MOQ Require

Monthly production capacity: 80K pcs

Specification Table

| Power | Regulation |

Temperature Rise |

Efficiency | Size(mm) | Power | Regulation |

Temperature Rise |

Efficiency | Size(mm) | |||

| (VA) | (%) | (℃) | (%) | OD | H | (VA) | (%) | (℃) | (%) | OD | H | |

| 50VA | 12.5% | 45℃ | 88% | 89 | 36 | 900VA | 4.6% | 65℃ | 95% | 152 | 75 | |

| 75VA | 12.5% | 55℃ | 88% | 89 | 42 | 950VA | 4.5% | 65℃ | 95% | 162 | 71 | |

| 100VA | 11.0% | 55℃ | 89% | 100 | 38 | 1000VA | 4.5% | 65℃ | 95% | 162 | 72 | |

| 150VA | 9.0% | 55℃ | 90.5% | 106 | 43 | 1100VA | 4.4% | 70℃ | 95.0% | 162 | 75 | |

| 200VA | 8.0% | 55℃ | 92.0% | 114 | 50 | 1200VA | 4.3% | 70℃ | 95.2% | 163 | 78 | |

| 250VA | 7.6% | 55℃ | 92.5% | 116 | 50 | 1300VA | 4.2% | 70℃ | 95.3% | 172 | 76 | |

| 300VA | 7.0% | 55℃ | 93.0% | 122 | 56 | 1400VA | 4.1% | 70℃ | 95.4% | 172 | 79 | |

| 350VA | 6.5% | 60℃ | 93.3% | 123 | 57 | 1500VA | 4.0% | 70℃ | 95.5% | 172 | 84 | |

| 400VA | 5.8% | 60℃ | 93.5% | 131 | 57 | 1600VA | 4.0% | 75℃ | 95.5% | 180 | 88 | |

| 450VA | 5.6% | 60℃ | 93.7% | 121 | 58 | 1700VA | 4.0% | 75℃ | 95.5% | 180 | 90 | |

| 500VA | 5.5% | 60℃ | 94.0% | 132 | 63 | 1800VA | 3.9% | 75℃ | 95.5% | 180 | 93 | |

| 550VA | 5.4% | 60℃ | 94.0% | 132 | 68 | 1900VA | 3.9% | 75℃ | 95.5% | 181 | 94 | |

| 600VA | 5.2% | 65℃ | 94.2% | 142 | 64 | 2000VA | 3.8% | 75℃ | 95.5% | 181 | 100 | |

| 650VA | 5.0% | 65℃ | 94.3% | 142 | 69 | 2300VA | 3.5% | 75℃ | 96.0% | 195 | 93 | |

| 700VA | 4.8% | 65℃ | 94.5% | 142 | 72 | 2500VA | 3.5% | 75℃ | 96.2% | 196 | 94 | |

| 750VA | 4.7% | 65℃ | 94.5% | 142 | 75 | 2600VA | 3.4% | 75℃ | 96.3% | 196 | 99 | |

| 800VA | 4.7% | 65℃ | 94.5% | 152 | 70 | 2900VA | 3.3% | 75℃ | 96.4% | 206 | 105 | |

| 850VA | 4.6% | 65℃ | 94.6% | 152 | 72 | 3000VA | 3.2% | 75℃ | 96.4% | 206 | 106 | |

Toroidal Transformer Main Materials (IQC process)

All the material is inspected strictly with ISO9001:2015 quality program.

Core: appearance inspection and core loss test.

Copper wire: pinhole test and coat of adhesion test

Toroidal Transformer Process

Transformer Testing Items

Two mounting way for choice.

1. Rubber + Metal disk Assembly

2. Epoxy in the centre